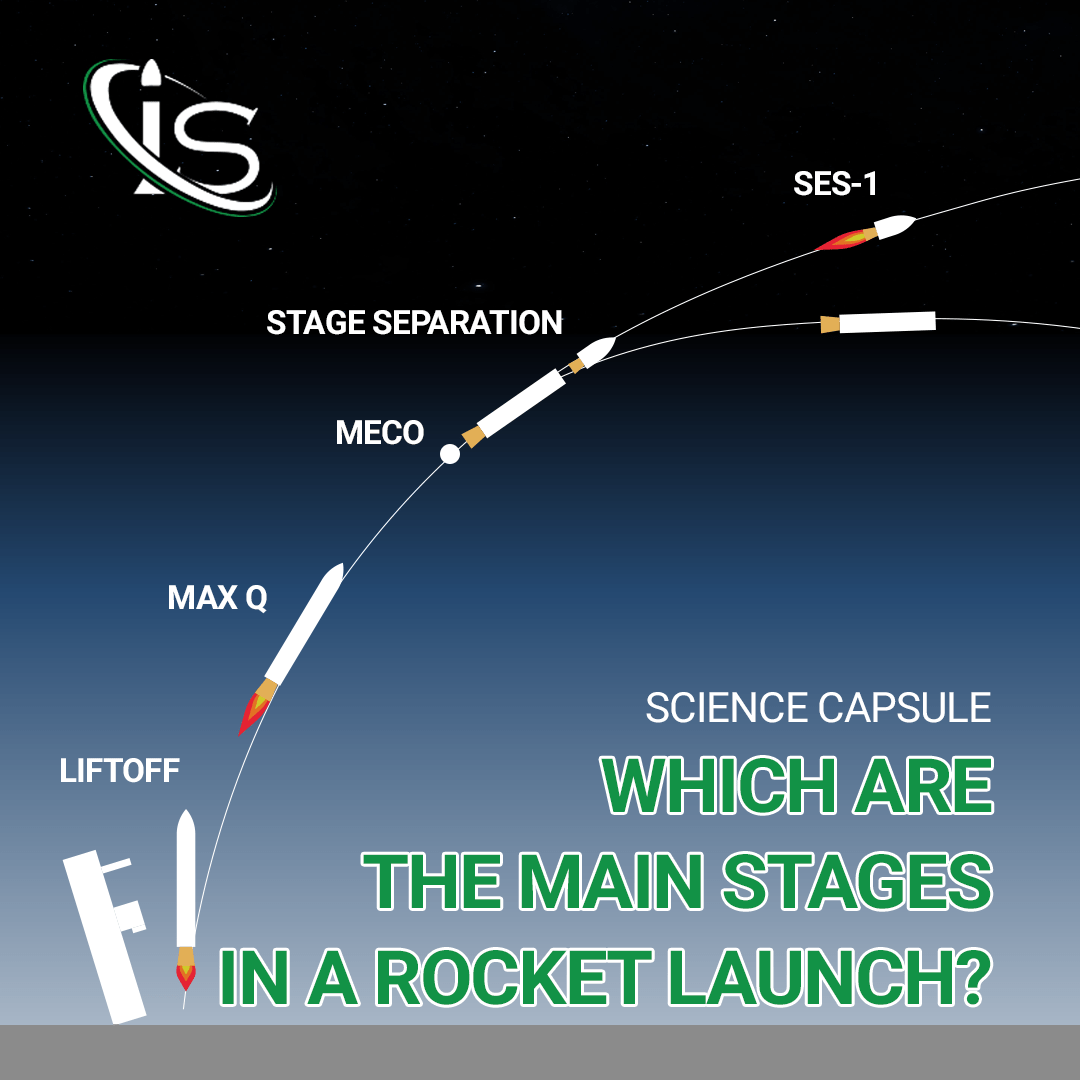

At the liftoff the thrust needed by the rocket refers to the force required to overcome its weight. The greater the weight, the greater the required force will be. The weight of the rocket is comprised by several parts; the most important for this post are the structure, the propellant and the payload. The payload represents just a small portion of the entire mass, while the propellant is one of the largest parts.

The maximum achievable velocity for a rocket, also known as the Tsiolkosky rocket equation, is given by the following:

![]()

where ![]() is the effective exhaust velocity,

is the effective exhaust velocity, ![]() is the final dry mass and

is the final dry mass and ![]() is the initial total wet mass.

is the initial total wet mass.

A good solution for this problem is the rocket staging, which allows for the split of the delta-v into fractions. Specially, upper stages reduce dry mass by discarding the deadweight of the used lower stages. This lightens the weight of the vehicle to achieve orbital velocity.

As an introduction to staging, it’s important to note that each stage contains its own engine, its own propellant, and can be optimized for the specific operating conditions. They can have different types of rocket engines, like Vega, which has three solid engines and one liquid, making it very suitable for the last stage that needs flexibility and precision in the maneuvers. In the Solid and Liquid post, there is a recap of the pros and cons of the type of rocket engine.

Why is staging advantageous? By decreasing the total weight, it reduces the amount of propellant needed and, therefore, the cost.

Does staging present some disadvantageous? Well, the major con is the risk of failure that increases for each added stage. There can be a separation failure, an ignition failure, or even a stage collision.

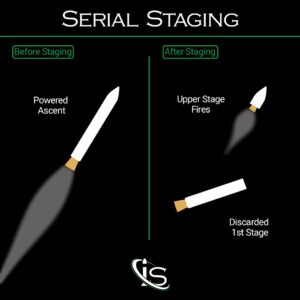

Serial Staging

Serial staging is characterized by stages being one on top of the other. The first stage is bigger than the second because it has to move more weight. A serial-stage rocket mission starts with the ignition of the first stage; when the propellant is burned, the separation between stages occurs and the second smaller stage is ignited. This process is repeated through all the stages, until the last one reaches the orbital velocity.

Not every rocket has the same number of stages: for example, Falcon 9 only has two stages, while Vega has four.

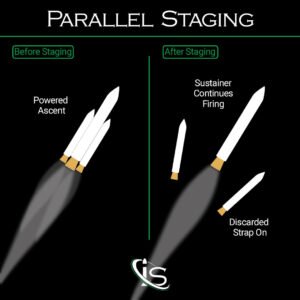

Parallel Rocket Staging

Parallel staging is characterized by small lateral stages, commonly referred to as stage “0”, strapped onto a central sustainer rocket. The boosters are all ignited together, and, when the propellant finishes, the separation occurs, and the sustainer continues its road to the target orbit.

There are a lot of rockets, like PSLV, Falcon 9, Ariane 5, that use both parallel and serial staging. The liftoff is operated by the boosters, and, when their propellant is burned, they separate from the master rocket. When the first stage of the rocket burns all the propellant there is, the serial stage separation begins, and the upper stage starts propelling the payload.